HDPE Pipe Welding Machines Supplier

HDPE Pipe Welding Machines/HDPE Pipe Welding Machines Supplier/HDPE Pipe Welding Machines Manufacturer/Industrial HDPE Pipe Welding Machines Manufacturer/Customized HDPE Pipe Welding Machines Supplier/

Table of Contents

Introduction

MK Polyplast stands tall as one of the most distinguished HDPE pipes welding machine manufacturers in Gujarat, India. With a reputation built on precision engineering and top-notch quality, we take pride in producing cutting-edge welding machines. Our expertise lies in crafting machines that ensure seamless joints, robust connections, and impeccable performance. When it comes to HDPE pipes welding, trust MK Polyplast for machines that set the industry standard. We are the best Customized HDPE Pipe Welding Machines Supplier.

High-quality piping systems are essential to the efficient movement of gas, water, and other fluids in the construction of modern infrastructure. High-Density Polyethylene (HDPE) is a polymer that is frequently used in pipes because of its strength, flexibility, and ability to withstand environmental stress. HDPE pipe welding gear is essential for safely and effectively joining HDPE pipes. Your hunt for a trustworthy supplier of HDPE pipe welding machines is over if you choose MK Polyplast.

Why Choose HDPE Pipes?

Several businesses favour HDPE pipes because of their excellent qualities:

- Durability: Under ideal conditions, HDPE pipes have a reputation for surviving a long time—often more than 50 years.

- Corrosion Resistance: HDPE pipes are resistive to rust and chemical reactions, in contrast to metal pipes.

- Flexibility: Because of their ability to adjust, they are perfect for regions with uneven terrain or seismic activity.

- Lightweight: Compared to other materials, they are simpler to install and move.

- Eco-Friendly: HDPE lessens its impact on the environment and is recyclable.

Because of these benefits, HDPE pipes are an economical and environmentally friendly option for industrial, gas and water supply applications.

The Importance of HDPE Pipe Welding Machines

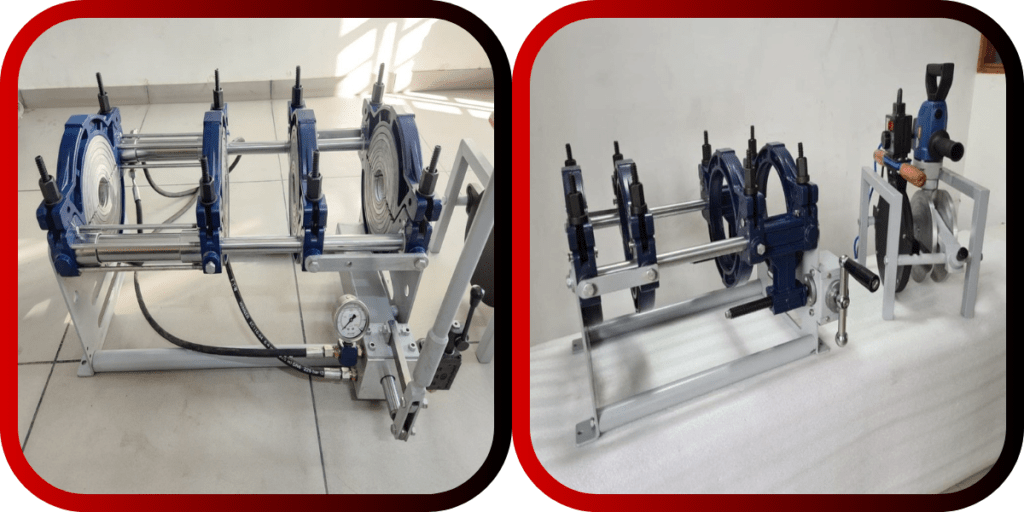

Using excellent welding tools during installation is crucial to maximising the advantages of HDPE pipes. Future maintenance problems are avoided by these devices, which guarantee a sturdy and leak-proof junction between pipes. The main categories of HDPE pipe welding techniques are as follows:

- Fusion Welding of the Butt

The most popular technique for joining HDPE pipes is this one. To create a seamless junction, the ends of two pipes are heated on a heating plate and then pressed together under regulated pressure. For pipes that have the same thickness and diameter, butt fusion welding works well. - Welding via Electrofusion

Specialised electrofusion fittings are employed in this process. Heating coils built into the fittings melt the pipe surface and form a strong connection. For repairs, this approach is frequently recommended. - Fusion Socket Welding

In socket fusion, a fitting and pipe are heated independently before being joined. This technique is frequently applied to pipes with a smaller diameter. - Welding by Extrusion

Extrusion welding ensures a solid connection by applying molten material along the junction using a heated extruder. HDPE sheets and custom fittings are the primary applications for this technique.

Only the best HDPE pipe welding machines can provide the accuracy and dependability needed for each of these techniques.

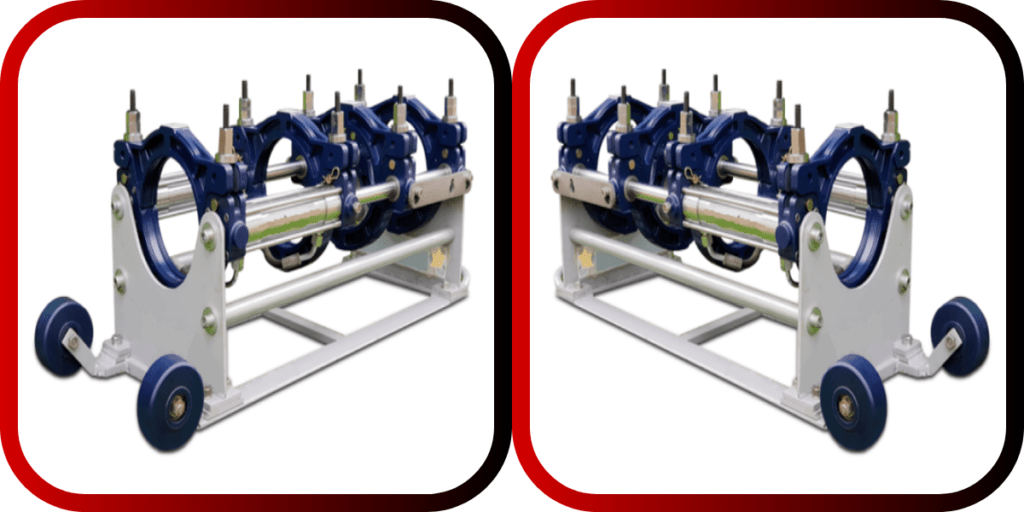

Key Features of HDPE Pipe Welding Machines

These essential features should be considered while choosing an HDPE pipe welding machine:

- Running Ease: Even inexperienced workers can use the equipment thanks to its simple controls and interfaces.

- Durability: Long-term performance is guaranteed by machines constructed from premium materials.

- Portability: Machines that are small and light are simpler to move and use in far-off places.

- Temperature Control: A solid weld depends on precise temperature settings.

- Safety Features: To avoid overheating or operational accidents, modern machines have been fitted with safety features.

These criteria are met by the HDPE pipe welding machines that MK Polyplast offers, guaranteeing dependability and effectiveness for your projects.

Applications of HDPE Pipe Welding Machines

HDPE pipe welding machines are used in many different industries, such as:

- Water delivery Systems: Making sure that rural and municipal water delivery networks have leak-proof connections.

- Gas Distribution: Gas distribution is the process of securely connecting pipes in gas transportation networks.

- Irrigation: For effective water management in farming, irrigation is utilised.

- Industrial Piping: Ensuring dependability and longevity in the transportation of industrial fluids and chemicals.

- Sewage Systems: Establishing strong ties to handle wastewater.

These devices are a great advantage for contractors and infrastructure developers because of their versatility.

Why Choose MK Polyplast: Best HDPE Pipe Welding Machines Supplier

We at MK Polyplast are aware of how important HDPE pipe welding equipment is to maintaining effective piping systems. We are the best Industrial HDPE Pipe Welding Machines Manufacturer. Here are some reasons why we are a reliable supplier:

- High-quality Supplies: To ensure reliable performance, our welding machines are constructed with accuracy and advanced technology in mind.

- Broad Product Offering: We provide a range of technology that may be used with various welding techniques, such as electrofusion and butt fusion.

- Professional Advice: To help you in selecting the best machine for your project, our team of experts offers technical support and advice.

- Competitive Pricing: Without sacrificing quality, we provide affordable solutions.

- After-Sales Support: We continue to be dedicated after the sale. To guarantee efficient operations, we offer maintenance, training, and replacement parts.

- Proven Track Record: We have gained the confidence of clients in a variety of industries thanks to our years of experience.

By selecting MK Polyplast, you are making an investment in dependable, long-lasting, and effective HDPE pipe welding machines that will improve the final results of your project.

Tips for Using HDPE Pipe Welding Machines

Use these pointers to get the most out of your HDPE pipe welding machine:

- Proper Pipe Preparation: Thoroughly clean the pipe ends to get clear of any moisture, oil, or grime.

- Establish the Proper Temperature: For the correct settings, stick to the manufacturer’s instructions.

- Ensure Proper Alignment: Use clamps or alignment tools to ensure proper alignment because misaligned pipes might result in weak joints.

- Monitor Heating Time: Keep an eye on the heating time because either too much or too little heat can affect the quality of the weld.

- Examine the Joint: To make sure the joint is strong and smooth after welding, visually examine it.

You may guarantee enduring and trustworthy relationships by adhering to these guidelines.

Conclusion: HDPE Pipe Welding Machines Supplier

MK Polyplast is a reliable brand when it comes to HDPE pipe welding machines. We are the perfect partner for all of your welding needs because of our wide choice of products, dedication to quality, and excellent client service. By selecting us, you’re investing in a durable solution that guarantees dependability and efficiency in your projects rather than just a machine. We provide you the best HDPE Pipe Welding Machines.

Our HDPE pipe welding machines will help you in creating smooth and permanent pipe connections, whether you work in the industrial, agricultural, or construction sectors. To learn more about our selection of goods and services, get in touch with MK Polyplast right now. Allow us to use our superior HDPE pipe welding machines to help you advance your projects.