HDPE Pipes Fitting Manufacturer

Introduction

Mk Polyplast take pride in being the Best UPVC Pipes Manufacturer in Ahmedabad. Our extensive product range includes HDPE Pipes Fittings, MDPE Pipes Fittings, Lateral Pipes Fittings, CPVC & UPVC Pipes , PP Pipes , compression Pipes , Ball Valves, and Flanges. As a leading Lateral Pipes Manufacturer in India, we prioritize delivering top-quality and reliable products. Our UPVC Pipes are crafted for durability and optimal performance. Whether you’re in need of high-density polyethene pipes or precision-engineered , MK Polyplast is your trusted choice. We are committed to exceeding industry standards and ensuring customer satisfaction. Explore our range for comprehensive piping solutions that combine quality and innovation.

Selecting the best HDPE pipes and manufacturer is essential to guaranteeing sustainability, performance, and longevity in the quickly changing field of infrastructure and industrial solutions. MK Polyplast Private Limited stands out among India’s top firms in this field as a reliable and creative partner for both governments and corporations. Due to their better performance and cost advantages, HDPE (High-Density Polyethene) pipes and have become an industry favourite as demand for effective fluid transport systems—whether for water supply, sewage, irrigation, mining, or industrial applications—grows. Let’s examine how MK Polyplast, a leading manufacturer of HDPE pipes and in India and abroad, is redefining expectations. We are the best HDPE Pipes Fitting Supplier.

What Makes HDPE Pipes and

One of India’s top producers of HDPE pipe fittings, MK Polyplast Private Limited is committed to creating high-performance polymer piping systems. With years of experience in the field and a dedication to innovation, MK Polyplast has established a reputation for excellence, dependability, and client satisfaction. High-Density Polyethylene (HDPE) piping solutions, which are renowned for their exceptional strength, flexibility, chemical resistance, and extended service life, are our area of expertise. Critical industries that our goods support include infrastructure development, agriculture, municipalities, and industry. We are the best HDPE Pipes Fitting Supplier in Gujarat.

Why Choose MK Polyplast

1. Superior Quality & Consistent Standards

- A reputed HDPE Pipes Fitting Manufacturer follows strict quality control processes and adheres to national and international standards, such as This ensures uniform wall thickness, precise dimensions, high pressure-bearing capacity, and excellent joint strength, resulting in leak-proof and long-lasting piping systems.

2. High Durability & Long Service Life

- HDPE pipes and Fitting are known for their exceptional durability. They are resistant to corrosion, rust, chemicals, and biological growth. When sourced from a trusted manufacturer, HDPE products can easily last over 50 years, even under harsh environmental and operating conditions.

3. Excellent Flexibility & Strength

- One of the major advantages of HDPE piping systems is their flexibility combined with high tensile strength. A professional HDPE Pipes & Fitting Manufacturer designs products that can withstand ground movements, vibrations, and pressure surges, making them ideal for underground and seismic-prone areas.

4. Leak-Proof & Safe Joints

- HDPE pipes and fittings are joined using butt fusion, electrofusion, or compression Fitting , creating a strong, homogenous joint. A reliable manufacturer ensures precise fitting designs and high-quality raw materials, minimising leakage risks and ensuring safe fluid or gas transportation.

5. Cost-Effective & Low Maintenance

- HDPE pipes and Fitting offer lower installation and maintenance costs compared to traditional piping materials. Lightweight construction reduces transportation and labour costs, while its resistance to scaling and corrosion minimises long-term maintenance expenses.

6. Environment-Friendly Solution

- HDPE is 100% recyclable and environmentally safe. A responsible HDPE Pipes & Fitting Manufacturer uses eco-friendly manufacturing practices, helping reduce carbon footprint and supporting sustainable infrastructure development.

7. Customisation & Technical Support

- Leading manufacturers provide customised HDPE pipes and Fitting based on project requirements, pressure ratings, and dimensions. They also offer technical guidance, installation support, and after-sales service, ensuring smooth project execution.

8. Eco-Friendly & Sustainable

- A professional HDPE pipe Fitting manufacturer focuses on environmentally responsible production. HDPE is recyclable, non-toxic, and energy-efficient to produce, making it an ideal choice for sustainable infrastructure and water management projects.

9. Customisation & Technical Support

- Leading manufacturers provide custom sizes, pressure ratings, and application-specific solutions. In addition, they offer technical guidance, installation support, and after-sales service to ensure smooth project execution and optimal system performance.

10. Reliable Supply & Timely Delivery

- An experienced HDPE pipe Fitting manufacturer has strong production capacity and logistics support, ensuring consistent supply and on-time delivery. This helps avoid project delays and ensures uninterrupted workflow, especially for large-scale projects.

Applications of HDPE Pipes & Fitting

1. Water Supply & Distribution

- HDPE pipes and Fitting are extensively used in municipal water supply systems, residential water lines, and industrial water distribution networks. Their non-toxic nature, smooth inner surface, and resistance to scaling ensure safe and efficient transportation of potable water over long distances with minimal maintenance.

2. Agriculture & Irrigation Systems

- In the agricultural sector, HDPE pipes play a vital role in drip irrigation, sprinkler systems, and lift irrigation projects. Their flexibility allows easy installation across uneven terrains, while their UV resistance and high-pressure-bearing capacity make them ideal for long-term outdoor use.

3. Sewage & Drainage Applications

- HDPE pipes and Fitting are a preferred choice for sewer lines, drainage systems, and wastewater management. They offer excellent resistance to chemicals, abrasion, and biological growth, ensuring leak-proof joints and long-lasting performance in underground installations.

4. Industrial & Chemical Processing

- Industries rely on HDPE piping systems for chemical transfer, effluent lines, and process water applications. Their strong resistance to acids, alkalis, and corrosive chemicals makes them suitable for chemical plants, refineries, and manufacturing units.

5. Gas Distribution Networks

- HDPE pipes are widely approved for natural gas and LPG distribution systems. Their flexibility, impact resistance, and fusion-welded joints provide high safety standards, making them ideal for underground gas pipelines.

6. Mining & Slurry Transportation

- In mining operations, HDPE pipes are used for slurry transportation, tailings disposal, and dewatering systems. Their high abrasion resistance and ability to withstand harsh conditions ensure consistent performance in challenging environments.

7. Telecom & Electrical Cable Protection

- HDPE ducts and Fitting are commonly used for telecom, optical fibre, and electrical cable protection. They safeguard cables from moisture, soil pressure, and external damage, ensuring long-term reliability of communication and power networks.

8. Infrastructure & Construction Projects

- From road crossings and culverts to large-scale infrastructure projects, HDPE pipes and Fitting offer flexibility, strength, and ease of installation, making them a cost-effective and sustainable piping solution.

Specifications Table of HDPE Pipes Fitting

| Specification Parameter | HDPE Pipes | HDPE Fitting |

|---|---|---|

| Material | HDPE Pipes Fitting | Virgin HDPE (PE-100/PE-80) |

| Standard Compliance | IS 4984 / ISO 4427 | IS 7834 / ISO 14236 |

| Size Range (Nominal Diameter) | 20 mm – 1200 mm | 20 mm – 630 mm |

| Pressure Rating | PN 4 – PN 25 | PN 4 – PN 25 |

| Jointing Methods | Butt Fusion, Electrofusion, Mechanical | Butt Fusion, Electrofusion |

| Operating Temperature | Up to 60°C | Up to 60°C |

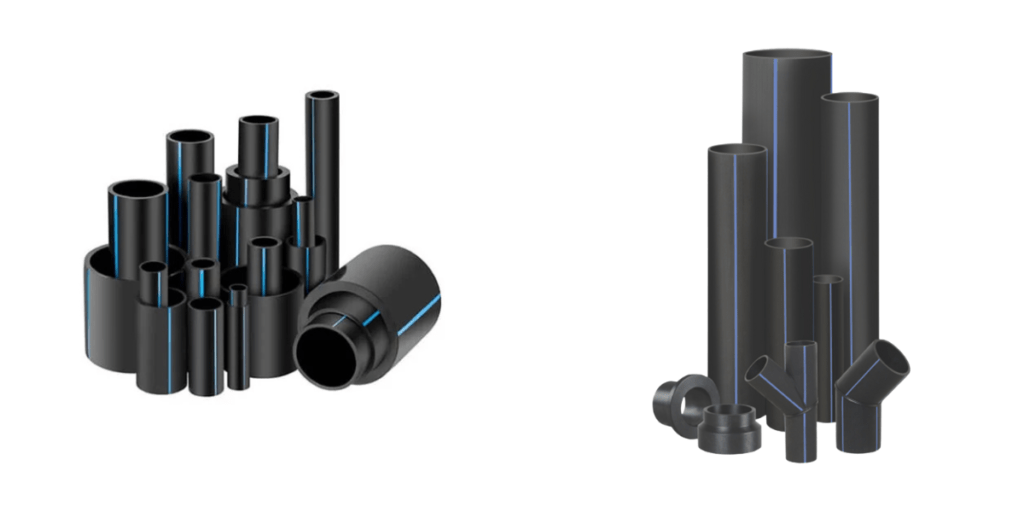

| Color | Black with colored stripes (Blue/Yellow/Orange) | Black with colored stripes (Blue/Yellow/Orange) |

| UV Resistance | Yes (Carbon Black) | Yes (Carbon Black) |

| Service Life | 50+ Years | 50+ Years |

| Application Areas | Water Supply, Irrigation, Sewage, Gas, Industrial | Water, Gas, Industrial Networks |

Benefits of HDPE Pipes Fitting

1. Exceptional Durability and Long Service Life

- HDPE pipes and Fitting are known for their outstanding durability. Manufactured using high-grade raw materials and advanced extrusion technology, they offer excellent resistance to corrosion, rust, chemicals, and environmental stress cracking. Unlike traditional metal pipes, HDPE products do not degrade easily, ensuring a service life of over 50 years under normal operating conditions.

2. Leak-Proof Jointing System

- HDPE pipes and Fitting support advanced jointing methods such as butt fusion, electrofusion, and socket fusion. These jointing techniques create a strong, homogenous pipeline with zero leakage. As a result, water loss is minimised, system efficiency is improved, and maintenance costs are reduced over time.

3. High Chemical and Corrosion Resistance

- One of the major benefits of HDPE piping systems is their excellent resistance to a wide range of chemicals, acids, and alkalis. A certified HDPE Pipes & Fitting Manufacturer ensures that products perform efficiently in aggressive industrial environments, wastewater systems, and chemical processing units without corrosion-related failures.

4. Lightweight and Easy Installation

- HDPE pipes are significantly lighter compared to metal or concrete pipes. This makes transportation, handling, and installation easier and more cost-effective. Reduced labour requirements and faster installation timelines help lower overall project costs while improving execution efficiency.

5. Excellent Flow Characteristics

- HDPE pipes have a smooth inner surface that minimises friction losses and prevents scaling or sediment build-up. This ensures consistent flow rates, improved hydraulic efficiency, and reduced pumping costs, even after years of operation.

6. Environmentally Friendly and Sustainable

- HDPE pipes and Fitting are recyclable and environmentally safe. A responsible HDPE Pipes & Fittings Manufacturer follows sustainable production practices, contributing to eco-friendly infrastructure development. Their long lifespan and low maintenance requirements also reduce environmental impact.

7. Wide Range of Applications

- HDPE pipes and Fitting are versatile and suitable for numerous applications, including potable water supply, agricultural irrigation, sewerage systems, gas pipelines, industrial fluid transfer, and cable protection. This adaptability makes them a cost-effective solution for diverse industries.

8. Low Maintenance and Lifecycle Cost

- Due to their corrosion resistance, flexibility, and leak-proof nature, HDPE piping systems require minimal maintenance. Over the lifecycle of the project, this translates into significant cost savings and uninterrupted system performance.

9. Compliance with International Standards

- A reputed HDPE Pipes & Fitting Manufacturer ensures that products meet national and international quality standards. Strict quality control, testing, and certification guarantee consistent performance, safety, and reliability for critical applications.

Types of HDPE Pipe Fitting

1. HDPE Water Supply Pipes

- These are engineered for potable water distribution and municipal water networks.

- Excellent hygiene standards

- Non-toxic and compliant with drinking water safety norms

2. HDPE Sewage & Drainage Pipes

- Built to handle wastewater, stormwater, and sewage.

- Resistant to chemical corrosion

- Designed for high flow capacity

3. HDPE Gas Distribution Pipes

- Manufactured under strict safety protocols for transporting natural gas.

- High pressure tolerance

- Long-term performance

4. HDPE Industrial Pipes

- Used in industries for chemical transfer, effluent disposal, and process piping.

- Customised to chemical compatibility

- High mechanical strength

5. HDPE Agricultural & Irrigation Pipes

- Ideal for drip irrigation, sprinkler systems, and farm water distribution.

- Lightweight and easy to install

- Durable for rural rugged use

Conclusion

In infrastructure and fluid management systems, the choice of piping material and manufacturer can significantly influence performance, cost efficiency, and longevity. As an industry-leading HDPE Pipes Fitting Manufacturer, MK Polyplast Private Limited offers unmatched product quality, comprehensive solutions, and dedicated customer support that empower projects of all sizes to succeed. We are the best HDPE Pipes Fitting Supplier in Ahmedabad.

MK Polyplast offers HDPE pipes and Fitting that offer long-term value, dependability, and peace of mind, whether you’re organising a sizable municipal project, an agricultural irrigation network, an industrial fluid system, or a commercial development.