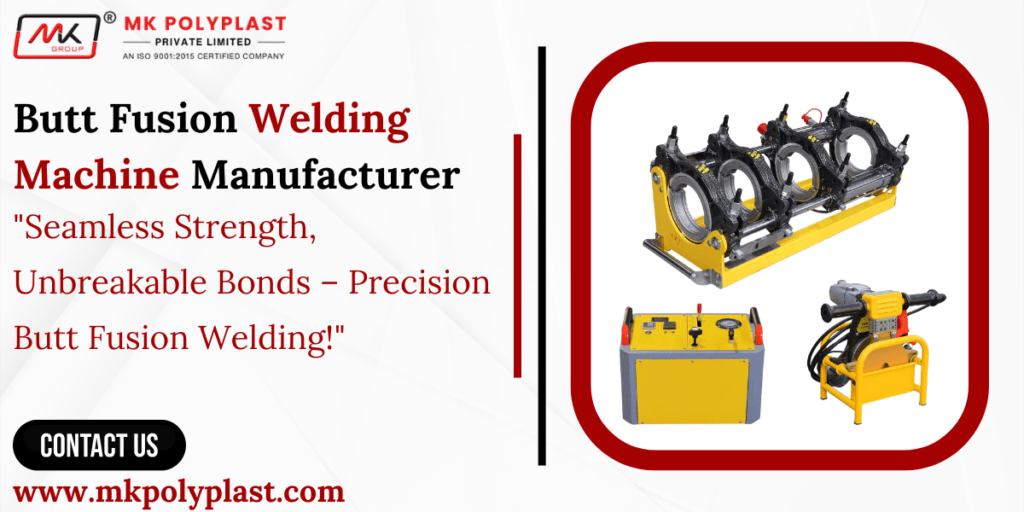

Butt Fusion Welding Machine Manufacturer

Butt Fusion Welding Machine/Butt Fusion Welding Machine Manufacturer/Butt Fusion Welding Machine Supplier/Butt Fusion Welding Machine Manufacturer in Ahmedabad/Manufacturer of Butt Fusion Welding Machine/

Table of Contents

Introduction

For 15 years, MK Polyplast has reigned as Gujarat’s leading pipe and fitting manufacturer, renowned for unwavering quality, forward-thinking innovation, and affordability. Whether you need pipes, fittings, bathroom upgrades, or water storage solutions, MK Polyplast delivers excellence. Their Best Quality HDPE Pipes Fittings guarantee durability and reliability, while their High Quality MDPE Pipes stand the test of time. Choose MK Polyplast for all your piping needs and experience top-tier products with dedicated service. We are the best Butt Fusion Welding Machine Manufacturer in Ahmedabad.

In the construction and fabrication sectors, welding is crucial. When it comes to joining thermoplastic materials, Butt Fusion Welding is one of the most popular welding techniques. Joining pipes and fittings is the main application for this welding technique in a variety of industries, including water treatment, plumbing, oil and gas, and construction. Knowing how butt fusion welding machines operate, their uses, and why picking a reputable manufacturer like MK Polyplast can make all the difference is essential if you need dependable and high-performing machines.

What is Butt Fusion Welding?

In butt fusion welding, two thermoplastic pieces—usually polyethylene, polypropylene, or other thermoplastic pipes—are heated and fused together using pressure and heat. Two pipe sections are heated until their ends are molten, and then they are pressed together to create a solid bond. This method ensures permanent performance in piping systems by producing a seamless, robust, and durable joint that is impervious to leaks.

High-quality welds are produced more quickly and easily thanks to the use of specialized Butt Fusion Welding Machines, which automate the heating and joining of pipes.

How Does Butt Fusion Welding Work?

There are four primary steps involved in butt fusion welding:

- Pipe Preparation: To guarantee that the pipe ends are smooth and flat, they are meticulously cut. To guarantee a strong weld, any contamination or debris on the surfaces is cleaned.

- Heating the Pipe Ends: To melt the material, the pipe ends are subsequently heated using a heated plate or heating element. The kind of thermoplastic being used and the pipe’s thickness determine the precise temperature and duration.

- Joining the Pipes: Pipe joining involves pressing the pipes together under controlled pressure after the pipe ends have melted. The molten material is forced to fuse under this pressure, forming a solid, uniform joint.

- Cooling and Solidification: The pipes are given time to cool and solidify following their joining. The material and pipe size affect how long it takes to cool. The joint offers a durable and efficient solution once it has cooled and grown as strong as the original pipe.

Advantages of Butt Fusion Welding

- Sturdy and Solid Joints

A seamless, continuous joint that is just as strong as the original material is produced by butt fusion welding. Long-term performance in demanding applications is guaranteed by the joint’s resistance to external pressures and ability to withstand leaks. - Adaptability

Large industrial pipes and pipes with small diameters can both be welded using this technique. It is extensively utilized in sectors like sewage systems, gas distribution, and water supply. - Economical

Because it eliminates the need for extra fittings like flanges, unions, and elbows, butt fusion welding is an economical technique. As a result, installation time and material costs are decreased. - Leak- Proof

Butt Fusion Welding produces joints that are completely fused, eliminating any openings or crevices where leaks could happen. This is especially important in sectors of the economy where leaks can lead to expensive repairs and environmental harm. - Decreased Maintenance

Butt Fusion Welded joints require very little care after installation.The system will last longer thanks to the joints’ durability and ability to withstand high pressures and stresses.

Applications of Butt Fusion Welding

Applications and industries where thermoplastic pipes and fittings need to be joined together use Butt Fusion Welding. Butt Fusion Welding is used in several key industries, such as:

- Sewage and Water Systems

Butt Fusion Welding is frequently utilized in sewage and water supply systems in municipalities. Water and waste move through the pipes without any leaks thanks to the welded joints. - Gas and Oil Pipelines

High-pressure pipelines that carry gas and oil over great distances are joined by Butt Fusion Welding in the oil and gas sector. Leaks that could result in major mishaps are avoided thanks to the pipeline’s welded joints, which guarantee its integrity. - Petrochemical and Chemical Industries

Pipes are joined in chemical and petrochemical facilities using Butt Fusion Welding. Because it produces strong, resistant joints that reduce the chance of leaks, the technique is especially useful when handling corrosive fluids. - Systems for Agricultural Irrigation

Butt Fusion Welding is used in agriculture to join irrigation pipes, guaranteeing that water reaches crops efficiently. Water is efficiently and waste-free delivered to the plants thanks to the leak-proof joints. - Mining Sector

Butt Fusion Welding is used in the mining sector to connect pipes that carry chemicals and slurry. The severe conditions present in mining operations can be tolerated by the welded joints.

Why Choose MK Polyplast: Best Butt Fusion Welding Machine Manufacturer

MK Polyplast is a prominent manufacturer of Butt Fusion Welding Machines, renowned for its quality, innovation, and customer satisfaction. MK Polyplast, a reputable supplier of welding equipment, provides a selection of premium Butt Fusion Welding Machines that are made to satisfy the demands of different industries. We are the best Butt Fusion Welding Machine Supplier. The following justifies making MK Polyplast your top pick:

- Assurance of Quality

The Butt Fusion Welding Machines from MK Polyplast are constructed from the best materials and put through a rigorous testing process to guarantee that they satisfy international standards. Every machine is built to last and perform exceptionally well. - Innovative Technology

Modern technology is incorporated into MK Polyplast’s welding machines. Advanced temperature and pressure control features on the machines guarantee accurate and reliable welding results. - Options for Customization

MK Polyplast is aware that various projects call for various approaches. You can choose the welding machine specifications that best meet your needs thanks to their customizable options. - Excellent Customer Service

MK Polyplast is dedicated to offering top-notch customer support. Their staff is available to help you with any questions or technical concerns at any time, from pre-purchase consultations to post-purchase assistance. - Competitive Rates

Butt Fusion Welding Machines from MK Polyplast are reasonably priced, giving you excellent return on your investment. Their machines offer the best value in terms of both quality and price. - Numerous Products

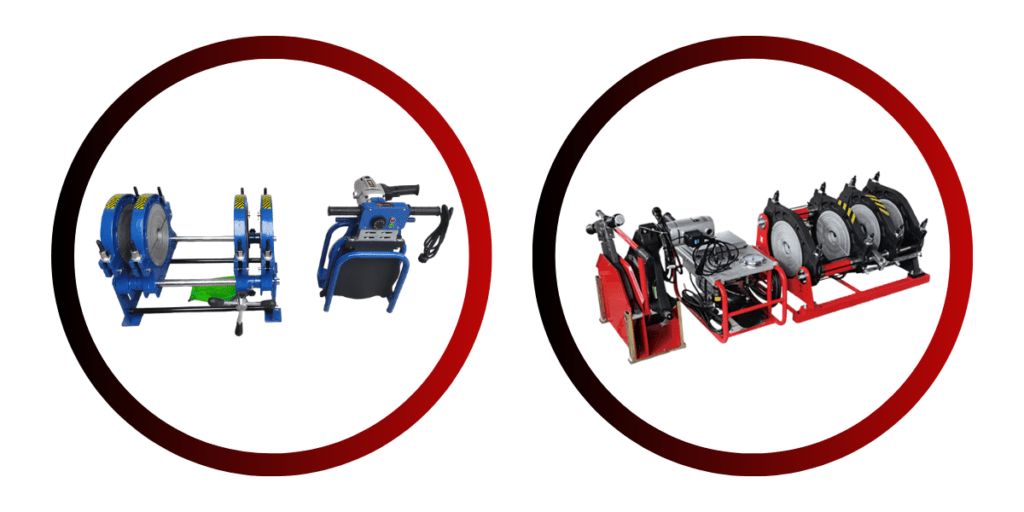

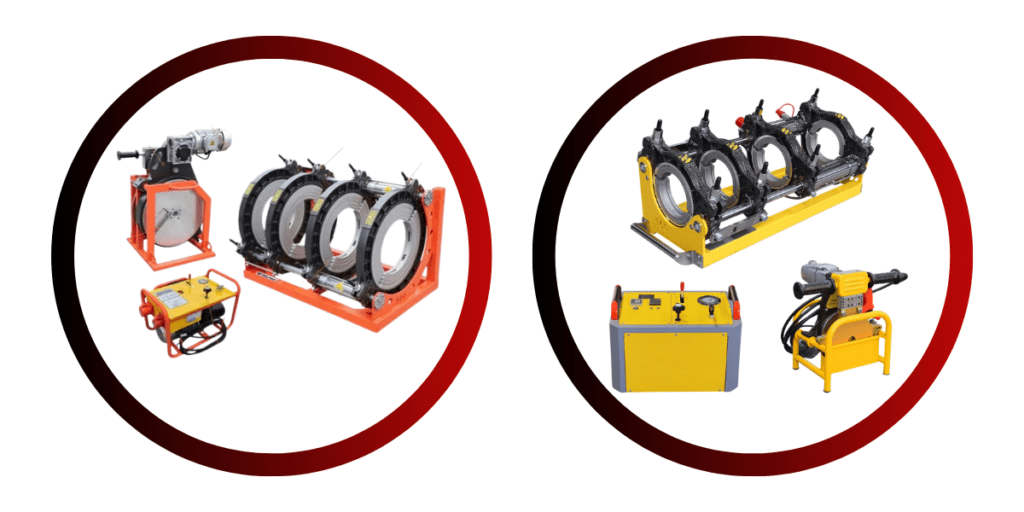

MK Polyplast offers a large selection of products to satisfy your needs, whether you require fully automatic, semi-automatic, or manual Butt Fusion Welding Machines. - Global Reach

MK Polyplast has established a solid reputation for producing high-quality goods all over the world. They make sure that clients worldwide can take advantage of their excellent solutions by exporting their welding machines to many nations.

Conclusion: Butt Fusion Welding Machine Manufacturer

In industries ranging from oil and gas pipelines to water and sewage systems, butt fusion welding is a essential method for joining thermoplastic pipes. To create strong, durable, and leak-proof joints that guarantee the systems’ longevity and effectiveness, premium Butt Fusion Welding Machines are essential.

As a top manufacturer of Butt Fusion Welding Machines, MK Polyplast offers premium equipment that offers outstanding value, performance, and dependability. For all of your welding requirements, MK Polyplast is your reliable partner because of its emphasis on quality, innovation, and client satisfaction. We are the best Manufacturer of Butt Fusion Welding Machine.

Please contact MK Polyplast if you are searching for dependable Butt Fusion Welding Machines. Allow us to assist you in completing your welding projects successfully.