HDPE Tailpiece Pipe End Manufacturer

HDPE Tailpiece Pipe End/HDPE Tailpiece Pipe End Manufacturer/HDPE Tailpiece Pipe End Supplier/HDPE Tailpiece Pipe End Provider/HDPE Fittings Manufacturer/

Table of Contents

Introduction

For 15 years, MK Polyplast has reigned as Gujarat’s leading pipe and fitting manufacturer, renowned for unwavering quality, forward-thinking innovation, and affordability. Whether you need pipes, fittings, bathroom upgrades, or water storage solutions, MK Polyplast delivers excellence. Their Best Quality HDPE Pipes Fittings guarantee durability and reliability, while their High Quality MDPE Pipes stand the test of time. Choose MK Polyplast for all your piping needs and experience top-tier products with dedicated service. We are the best HDPE Tailpiece Pipe End Manufacturer.

HDPE (High-Density Polyethylene) pipes are the perfect answer for guaranteeing the efficient, long-lasting, and safe transportation of water and other fluids. These pipes’ strength, flexibility, and chemical resistance have completely changed how industries approach piping systems. The tailpiece pipe end is a vital part of the entire assembly and a necessary component of an HDPE piping system.

The definition of HDPE tailpiece pipe ends, their significance in industrial settings, and the reasons MK Polyplast Private Limited is the best HDPE tailpiece pipe end supplier for your requirements will all be covered in this article.

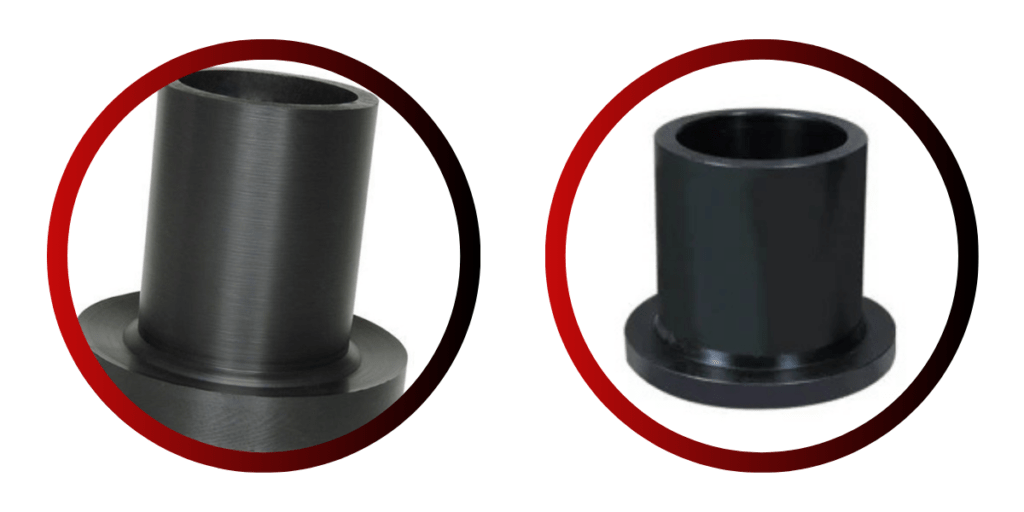

What Is an HDPE Tailpiece Pipe End?

A specialised fitting called an HDPE tailpiece pipe end is used to fasten the end of an HDPE pipe to a variety of other systems, including water transportation, industrial settings, and plumbing. It is meant to be fastened to the end of the pipe in order to facilitate its connection to valves, other pipes, or machinery.

In order to guarantee a tight and leak-proof connection, the tailpiece serves as an interface between the pipe and other parts. By stopping leaks and damage, these fittings are essential to preserving the piping system’s structural integrity.

Why Choose HDPE for Tailpiece Pipe Ends?

A common material used in the production of pipes and fittings, HDPE works especially well for tailpiece pipe ends. This is the reason:

- Durability

Extreme temperatures, moisture, and chemical exposure are just a few of the many environmental conditions that HDPE is extremely resilient to. Because of this, it is the perfect material for tailpiece pipe ends, which are frequently subjected to demanding industrial settings. - Resistance to Corrosion

HDPE resists corrosion better than metal pipes, which can rust or corrode over time. This guarantees that the tailpiece pipe ends will continue to be leak-free and operational for a longer span of time. - Economical

When weighed against alternatives such as PVC, metal, or stainless steel, HDPE is an economical material. It is a desirable option for commercial and industrial use since it provides outstanding durability without the high cost. - Flexibility

HDPE’s flexibility is one of its main benefits. Because of this characteristic, HDPE tailpiece pipe ends can be put in confined spaces without cracking or shattering when pressure is applied. - Leak-Free Performance

The purpose of HDPE tailpiece pipe ends is to provide a leak-proof connection. This is particularly important in sectors of the economy where even minor leaks can cause large losses or damage. Maximum security is guaranteed by the seamless fusion of the HDPE pipes and the tailpiece.

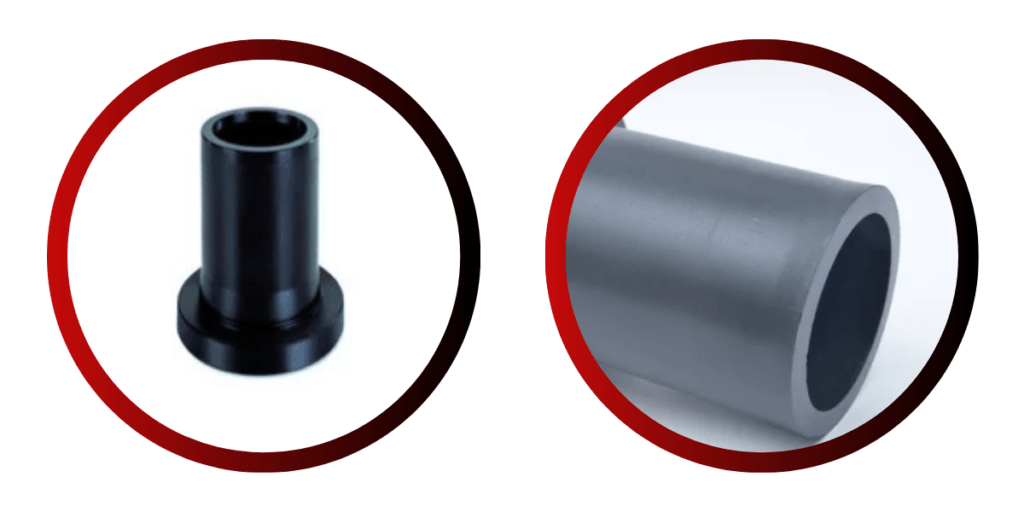

Types of HDPE Tailpiece Pipe Ends

HDPE pipe end fittings are available in a variety of shapes and sizes to suit a range of applications. Typical examples include:

- Butt Fusion Pipe End: The butt fusion method is used to weld these pipe ends to the pipe. To make a solid, leak-proof bond, the pipe ends are heated and then pressed together. Gas and water distribution systems frequently use butt fusion.

- Pipe End Electrofusion: Electrofusion creates a strong connection by heating the pipe and fitting with an electric current. This technique is effective and offers HDPE pipes a dependable, leak-proof connection.

- Mechanical Couplings: These are specially made pipe ends that join pipes together mechanically, eliminating the need for welding. They are frequently employed when welding is impractical.

- Flanged Pipe End: These pipe ends are easily connected to other flanged components because they have flanges on both ends. This kind is frequently utilised in industrial settings where it is necessary to disassemble pipes on a regular basis for maintenance.

- Compression Fittings: These pipe ends fasten the pipe to fitting connection with compression rings and nuts. This kind works well with home plumbing systems and pipes with a smaller diameter.

Applications of HDPE Tailpiece Pipe Ends

There are numerous industries that use HDPE tailpiece pipe ends, including but not restricted to:

- Systems for Water and Wastewater

HDPE pipes are utilised in municipal water and wastewater systems due to their durability and ability to withstand corrosion. In order to ensure that water flows freely without any leaks or contamination, HDPE tailpiece pipe ends assist in connecting pipes to other systems. - Farming

Durable piping is frequently needed in agricultural systems to move pesticides, fertiliser, and water. The safe and effective flow of liquids to crops is ensured by the dependable connections that HDPE tailpiece pipe ends offer for irrigation pipes. - Building

HDPE pipes are frequently used in construction to move a variety of materials, such as gases, chemicals, and water. In order to ensure seamless operations, tailpiece pipe ends are crucial for attaching these pipes to other buildings. - Industrial Applications

High-performance piping systems are necessary for industrial applications, such as factories and chemical plants. In these settings, HDPE tailpiece pipe ends are utilised to guarantee safe and impervious connections for pipes that handle a range of liquids and gases.

Why Choose MK Polyplast Private Limited: Best HDPE Tailpiece Pipe End Manufacturer

One reputable company in the production of HDPE tailpiece pipe ends is MK Polyplast Private Limited. We are the best HDPE Tailpiece Pipe End Supplier. The following explains why our products are unique in the market:

- Proficiency in HDPE Production

MK Polyplast has years of experience in the field and specialises in creating premium HDPE products, such as tailpiece pipe ends. Every product meets or surpasses industry standards thanks to our expertise. - Innovative Technology

The newest manufacturing technology is used at MK Polyplast to guarantee accuracy and excellence in each product we create. Recent technology ensures that our HDPE tailpiece pipe ends are long-lasting, leak-proof, and simple to install. - Comprehensive Range of Products

To satisfy the various needs of our customers, we provide a large selection of HDPE tailpiece pipe ends. MK Polyplast can provide you with a custom-designed product or a standard fitting. - Customer-Centric Approach

At MK Polyplast, we put the needs of our customers first. We collaborate closely with each client to fully understand their needs and provide solutions that are specifically designed to meet those needs. - Prompt Delivery

We are aware that every project has a time constraint. MK Polyplast is dedicated to timely product delivery, guaranteeing that your project moves forward without interruption. - Reasonably Priced

All of our products, including HDPE tailpiece pipe ends, are reasonably priced. Businesses of all sizes can stay within their budgets with the help of our affordable solutions.

Conclusion: HDPE Tailpiece Pipe End Manufacturer

Any HDPE piping system must have HDPE tailpiece pipe ends because they provide robust, durable, and leak-proof connections for a range of uses. To guarantee the performance and quality of these parts, selecting a suitable manufacturer is essential. We are the best HDPE Fittings Manufacturer.

Being a top producer of HDPE tailpiece pipe ends is something we at MK Polyplast Private Limited take great pride in. Because of our years of experience, emphasis on quality, and dedication to client satisfaction, we are a top choice for businesses worldwide.

Contact MK Polyplast right now to discover the difference in quality and service for durable, reasonably priced HDPE tailpiece pipe ends.